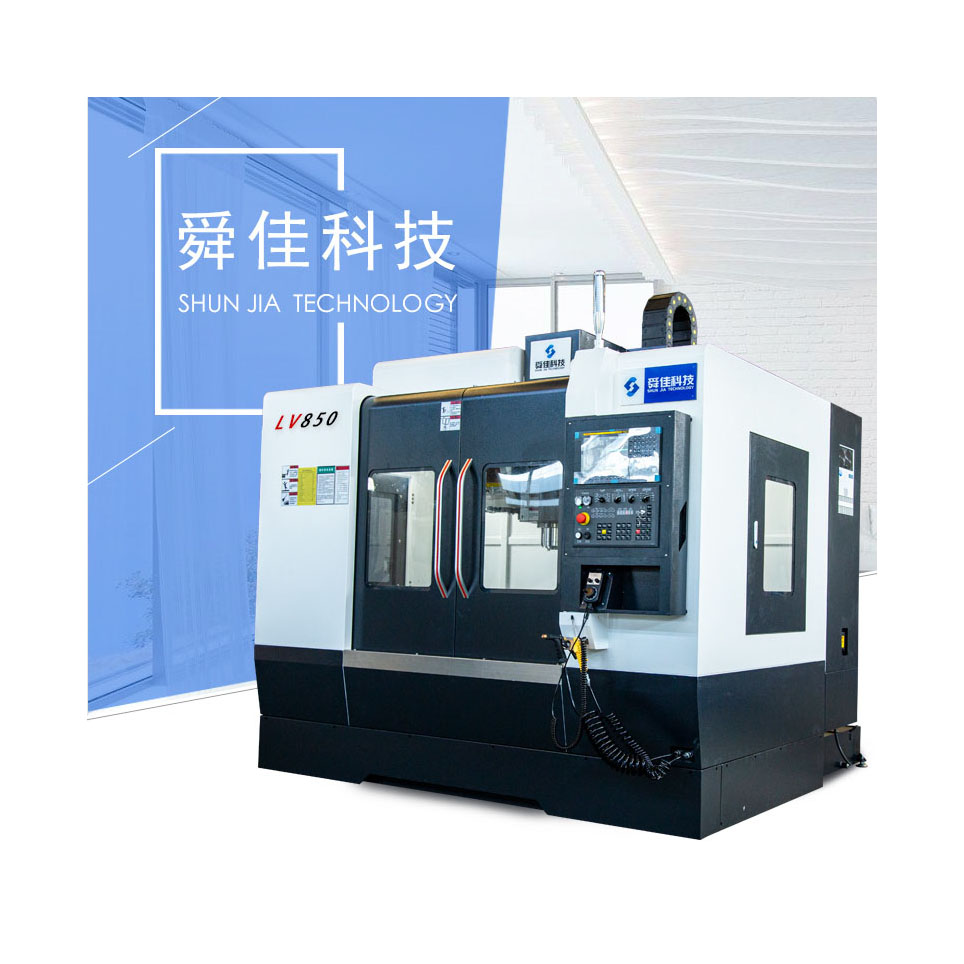

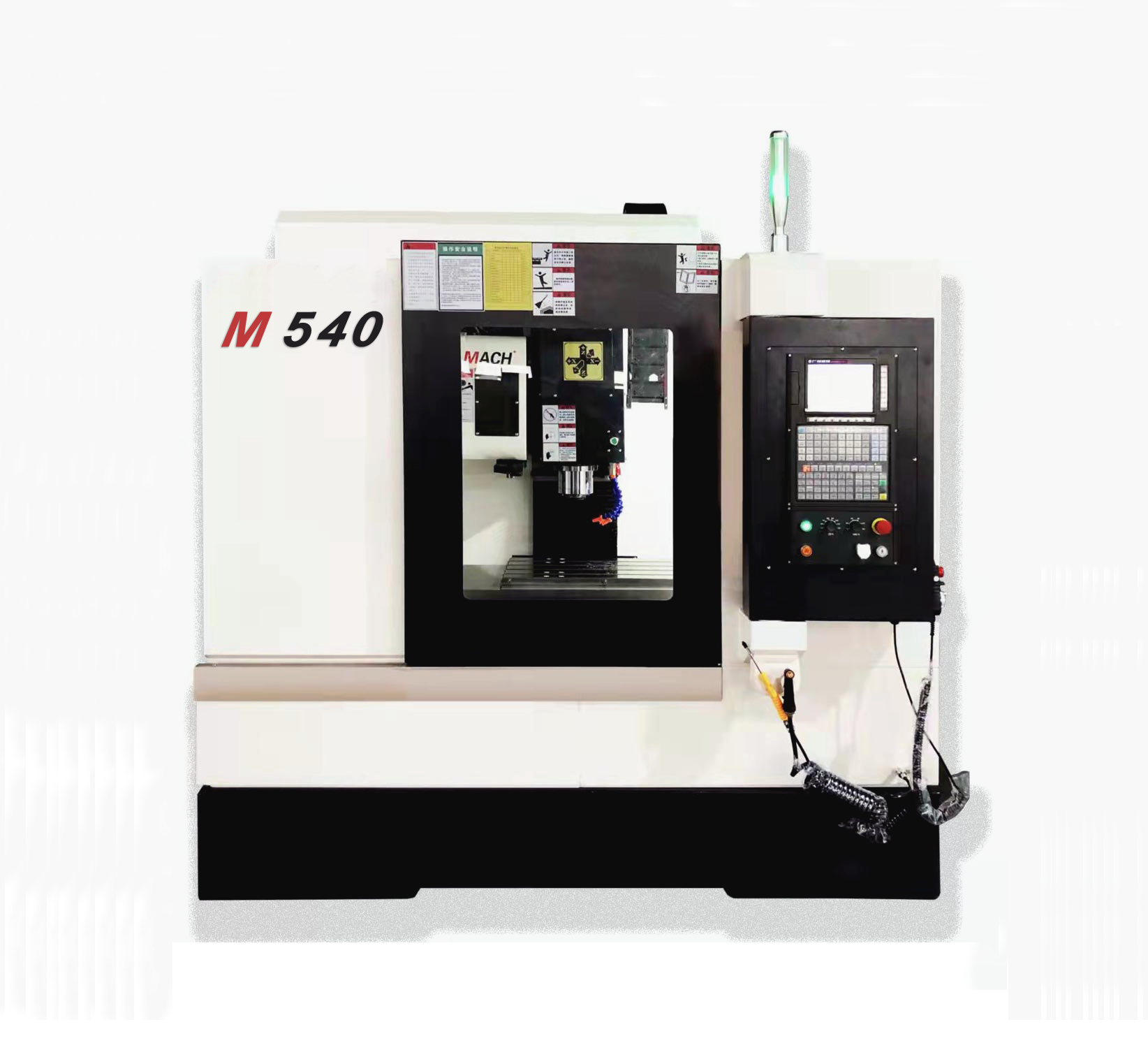

Hengda CNC M540 Machining Center

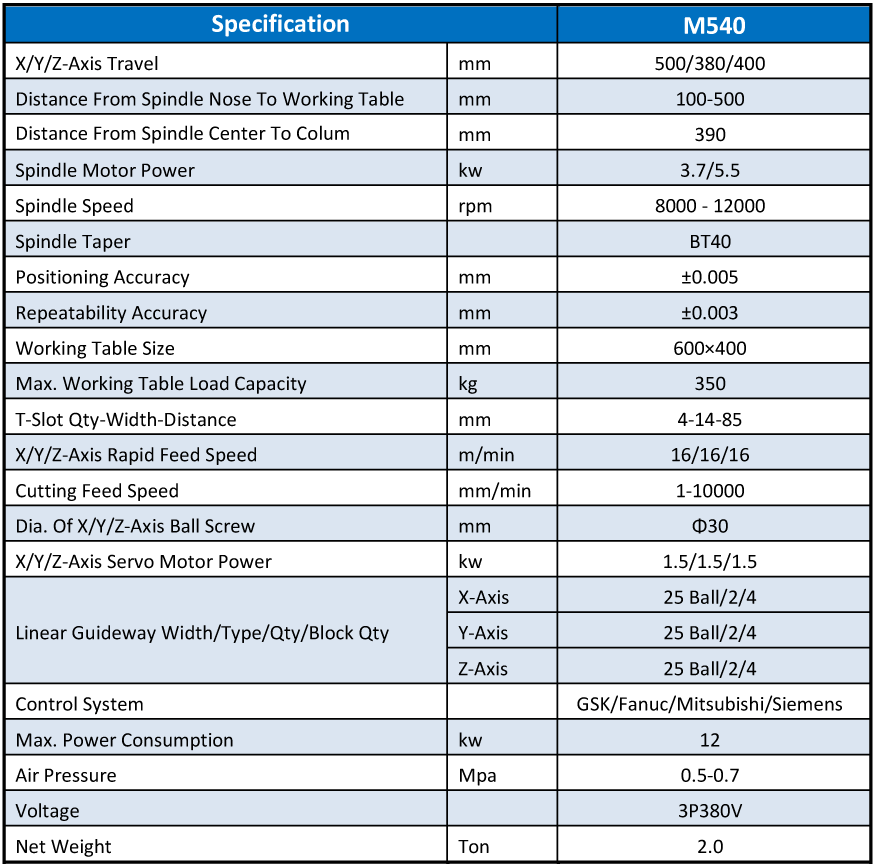

Travel 500/380/400, Table 600×400, Spindle 8000 - 12000 rpm BT40 3.7/5.5 kw, 16 Tools Armless ATC

Fanuc/Mitsubishi/Siemens/GSK Controller Optional, Support Configurations Customized

Hengda CNC High Precision Machining CenterM540

Parameters:

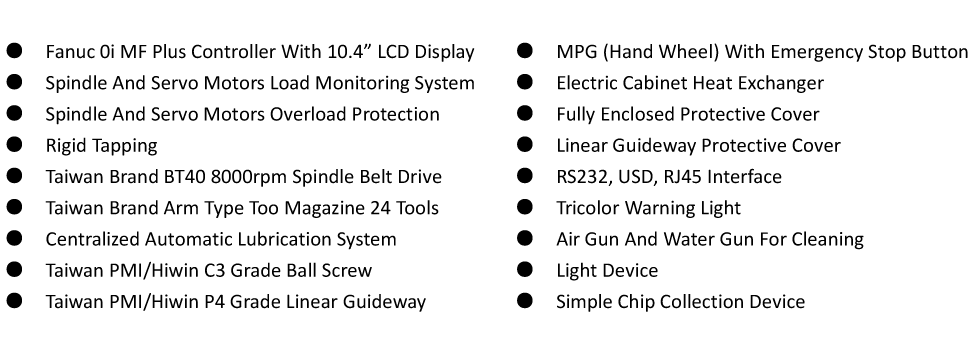

Standard Features:

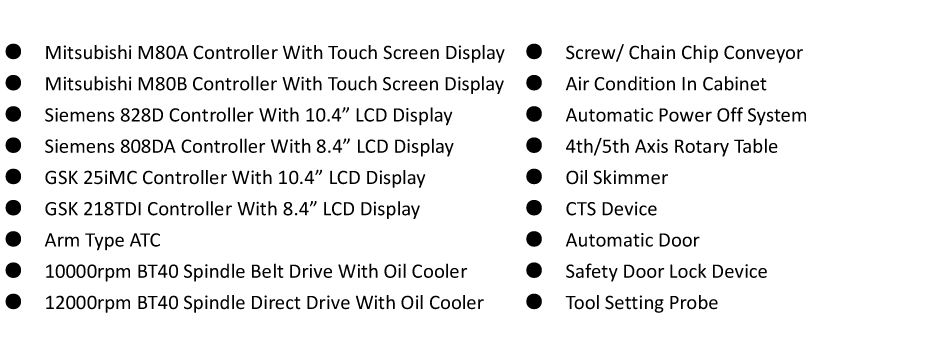

Optional Features:

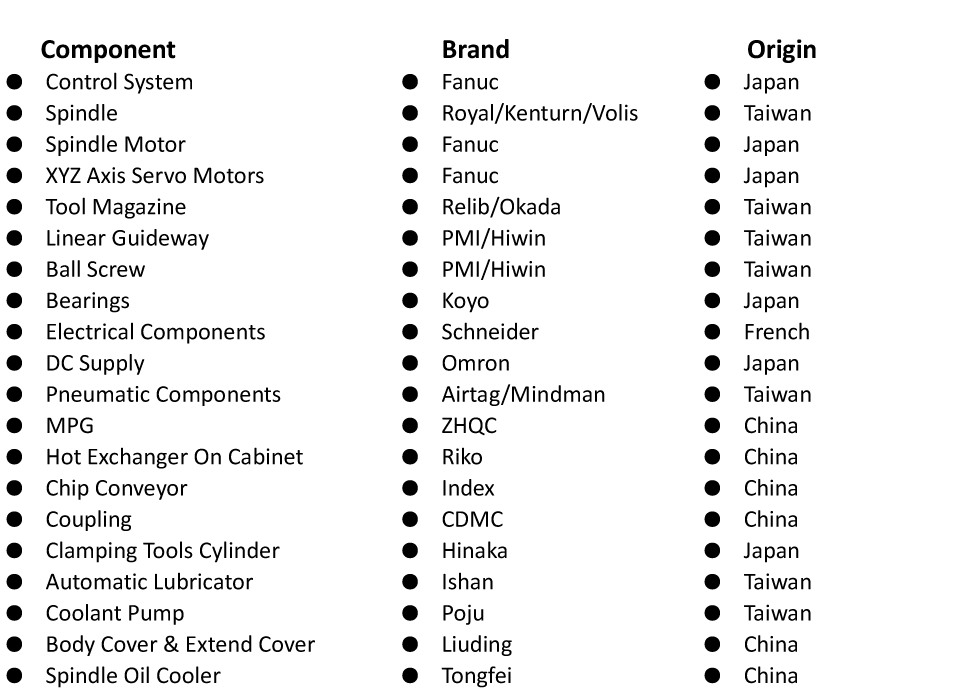

Components:

Advantage:

The overall framework is made of high grade casting iron with twice heat treatments and magnetic resonance. The natural aging relieves internal stress to ensure the lasting best rigidity and high precision.

The bed base assembling with the long span column design increases the contact area between the column and the base.

3 axes assembled with linear guideway, increase the processing strength and shock resistance significantly. The epoxy resin stick processing and artificial scraping grinding ensure the precision and stability.

The spindle assembled with high power servo motor, belt driving or direct driving is optional to provide high torque and wide range output.

Oil-water separation design.

The major outsourced components are all provided by foreign well-known brands and manufacturers to ensure best complete machine quality.

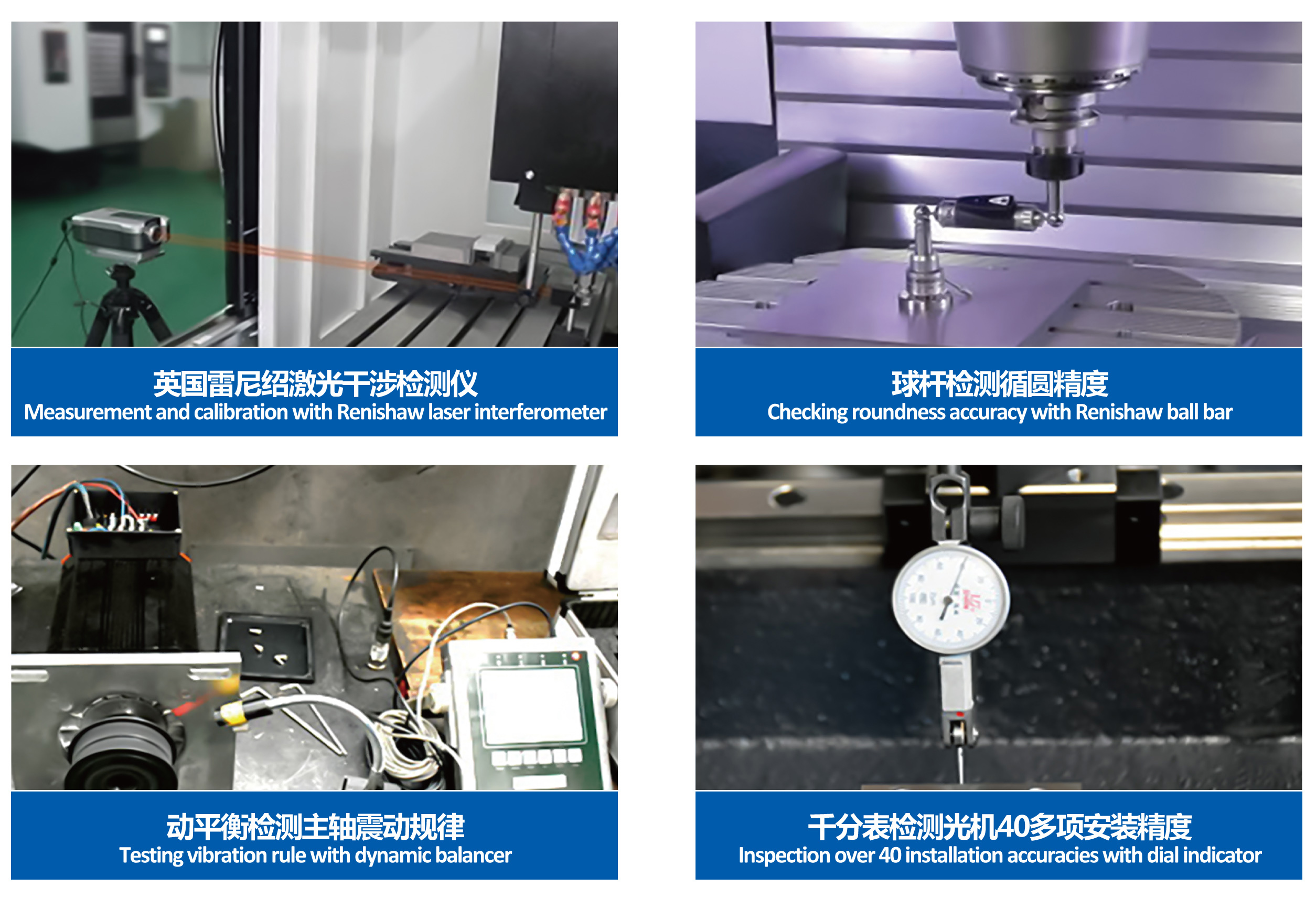

Professional Testing: